QUALITY

CONTROL

"Our customer requirements and customer satisfaction comes first, we are continuously improving our quality management system to provide the best we possibly can."

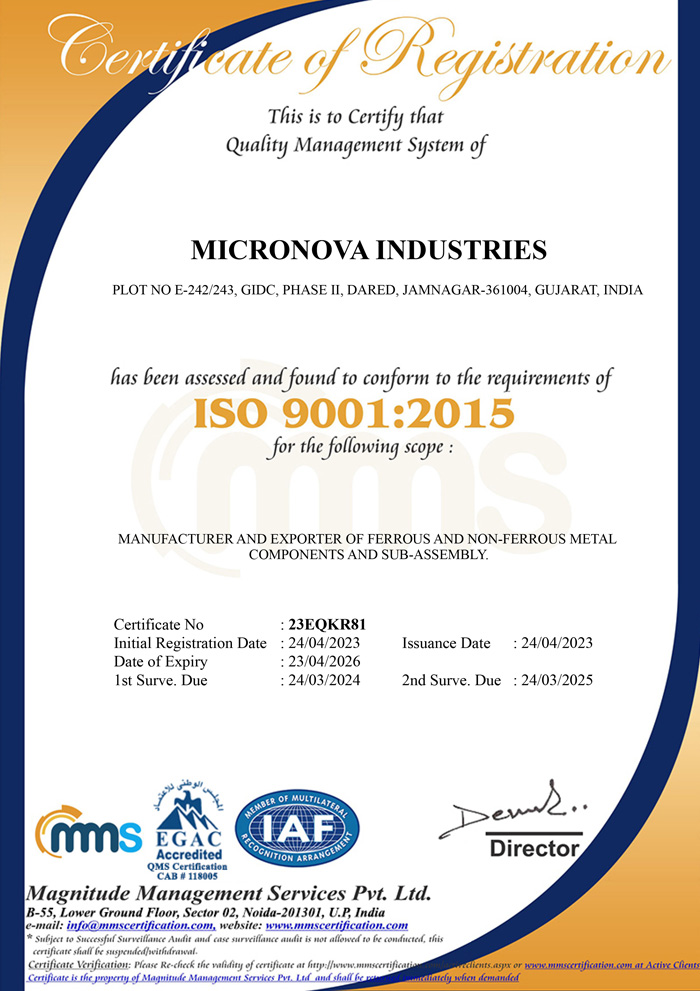

ISO 9001 Certificate

At MICRONOVA, we believe that quality isn't just a goal — it's a commitment. That's why ISO 9001 certification is not just important, it's essential — both for us and for our partners.

ISO 9001 is the world's most recognized and respected standard for quality management systems. It sets the benchmark for ensuring consistent performance, customer satisfaction, and continuous process improvement across all industries.